Requirements for Carbon Capture

Technologies for the capture and storage of CO₂ serve an important role in decarbonizing industrial processes. CCS plants are currently primarily being built where greenhouse gas is emitted during industrial processes in large quantities – in power plants that run on fossil, substitute or residual fuels, in the chemical industry, in oil and gas refineries, in the cement industry, in iron and steel plants, and in the maritime industry. One major effect of capturing and storing CO₂ is generating environmentally neutral energy, for example when producing blue hydrogen or providing liquefied CO₂ for heating purposes or process engineering. After the capture, CO₂ is fed into a compression stage where it is compressed to around 15 bar and -30 °C under high pressure so that it can be transported to the point of use or storage as a liquid phase.

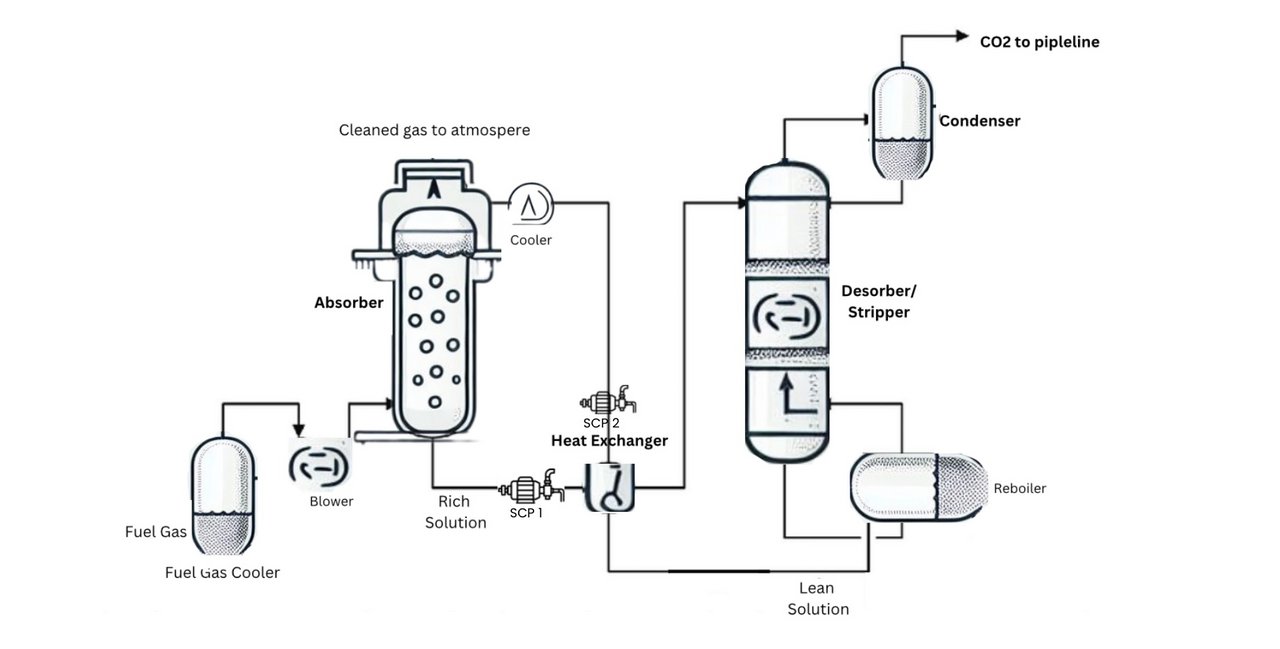

Application of Side channel pumps in Amine Scrubbing Solution

Flue Gas Entry: The exhaust gas stream, containing CO₂, enters the absorber column. Amine Shower: Inside the absorber, a shower of amine solution trickles down over packing materials that create a large surface area. The amine chemically reacts with the CO₂ in the flue gas. This reaction "scrubs" the CO₂ out of the gas stream, bonding it with the amine to form a CO₂-rich amine solution. The CO₂-rich amine solution exits the absorber and is pumped to a heat exchanger. (Side Channel Pump 1) The pre-heated amine solution then enters the desorber.In the desorber, heat is applied to break the chemical bond between the CO₂ and the amine, releasing pure CO₂ for further processing and storage. The regenerated lean amine solution (low in CO₂) exits the desorber and is cooled down in another part of the heat exchanger (Side Channel Pump 2) using the cooler CO₂-rich solution coming from the absorber. The cooled lean amine solution is then recycled back to the absorber to capture more CO₂, completing the cycle.

Phone: +49 (6226) 9201-0

Mail: applications@seroweb.de